Introduction to UVLACK

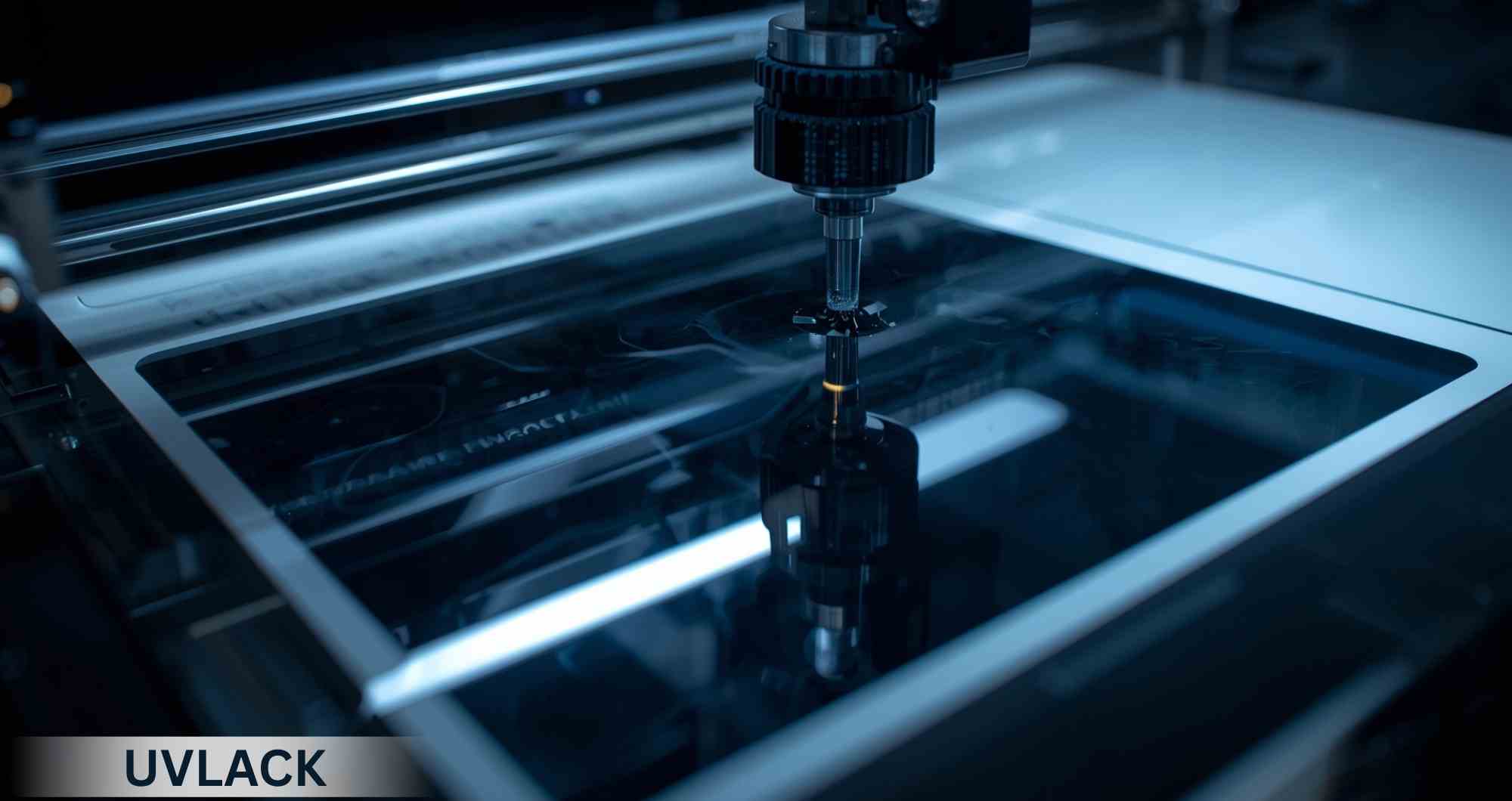

In the printing and packaging sectors, leaving a lasting image is crucial. That’s where UVLACK comes into play. This premium UV coating solution offers unmatched protection and a brilliant finish for labels and printed materials. If you’re looking to elevate your products while ensuring durability, UVLACK might just be the answer.

What makes this varnish so special? It combines advanced technology with practical applications, making it an essential choice for printers and manufacturers alike. Its versatility allows it to enhance various surfaces, providing a stunning visual impact without compromising quality.

In this article, we’ll explore what UVLACK is all about—its key features, compatibility with different surfaces, diverse applications in printing and packaging industries, as well as its numerous benefits over traditional alternatives. Whether you’re considering a switch or simply curious about upgrading your projects’ aesthetic appeal, you’ll find valuable insights here that can guide your decision-making process. Let’s dive in!

What is UV Varnish?

A specific coating called UV varnish is applied to printed goods.It utilizes ultraviolet light for curing, which makes it harden quickly upon exposure. This procedure produces a long-lasting finish that improves the aesthetic appeal of different surfaces.

UV varnish is mostly used to preserve and improve print quality. By forming a glossy layer over inks, it intensifies colors and boosts vibrancy. This results in more striking visuals that catch the eye.

The quick drying period of UV varnish is one of its noteworthy features.. Traditional coatings can take hours or even days to cure fully, while UV varnishes set almost instantly under UV lamps. This efficiency allows for faster production times in printing environments.

In addition to aesthetics, UV varnish offers significant protection against scratches and fading caused by environmental factors such as sunlight and moisture. Because of its durability, it is the ideal choice for goods that are exposed to wear and tear.Furthermore, UV varnishes are versatile; they can be used on a range of materials, including plastic films, cardboard, paper, and metal.Their versatility expands the spectrum of sectors in which they can be used.

Key Features of UVLACK

UVLACK stands out in the world of coatings due to its impressive durability. This premium UV coating is engineered to withstand daily wear and tear, making it ideal for high-traffic applications.Because of its durability, printed surfaces are guaranteed to keep their immaculate quality throughout time.

Another key feature is its rapid curing process. When exposed to UV light, UVLACK cures almost instantly, enabling faster production times and improved workflow efficiency. This quick turnaround is a game-changer for businesses looking to meet tight deadlines without sacrificing quality.

The varnish also offers exceptional gloss levels. It provides a sleek finish that enhances colors and adds depth to any label or packaging design. In addition to improving aesthetics, the shiny look draws customers’ attention on crowded shelves.

Furthermore, UVLACK boasts excellent adhesion properties on various substrates. Whether it’s paper, plastic, or metal surfaces, this varnish adheres effectively without compromising integrity or performance.

Its resistance to chemicals makes it suitable for diverse environments—from retail settings to industrial applications—ensuring labels remain intact even when faced with harsh conditions.

Types of Surfaces Compatible with UVLACK

UVLACK is highly versatile, making it compatible with a wide range of surfaces. This flexibility allows for various applications in the printing and packaging industries.

First and foremost, UVLACK works exceptionally well on paper products. Whether it’s coated or uncoated paper, this premium varnish enhances durability while providing a glossy finish that attracts attention.

Another surface type that benefits from UVLACK is cardboard. The robust nature of UVLACK ensures that labels and packaging created from cardboard maintain their visual appeal over time without compromising structural integrity.

Plastic substrates also show compatibility with UVLACK. Materials such as PET and PVC can be treated effectively to achieve vibrant colors and enhanced scratch resistance, which are vital for product labeling.

Metal surfaces aren’t left out either. With proper treatment, UVLACK can adhere beautifully to metals like aluminum or tinplate, delivering exceptional gloss and protection against environmental factors like moisture or corrosion. This adaptability makes UVLACK an excellent choice across various industries looking to elevate their branding efforts through high-quality finishes.

Applications in Printing and Packaging

UVLACK is an exceptional choice for various applications in printing and packaging. Its versatility makes it suitable for different materials, enhancing the overall aesthetic appeal of labels and products. This premium UV coating provides a glossy finish that not only elevates designs but also improves durability.

In the realm of labels, UVLACK offers superior protection against scratches, moisture, and fading. Whether it’s beverage bottles or cosmetic packaging, this varnish ensures that colors remain vibrant over time. The result is eye-catching branding that stands out on store shelves.

UVLACK adds a professional look to printed materials like brochures and business cards.. The smooth texture attracts attention while conveying quality to potential customers.By lowering glare from lighting conditions, it improves reading.

Packaging solutions benefit significantly from using UVLACK as well. Boxes and cartons coated with this varnish resist wear and tear during transit while maintaining their visual appeal at retail points. Such resilience increases customer satisfaction rates.

Digital printing processes are compatible with UVLACK too. This compatibility allows businesses to explore creative designs without compromising on durability or print quality.

Benefits of Using UVLACK

UVLACK offers numerous advantages that make it an ideal choice for various printing applications. First and foremost, its rapid curing process significantly enhances production efficiency.UVLACK dries almost immediately when exposed to ultraviolet light, in contrast to conventional coatings that need prolonged drying times. This saves time in the manufacturing cycle.

Another significant benefit of UVLACK is its durability. The high-quality formulation provides a robust protective layer against scratches, scuffs, and other forms of wear and tear. Labels and printed materials treated with this varnish maintain their pristine appearance over extended periods.

UVLACK also boasts excellent color vibrancy and gloss levels. It enhances the visual appeal of products by making colors appear more vivid while providing a shiny finish that attracts attention on shelves.

Moreover, using UVLACK can lead to cost savings in the long run due to reduced material usage. Its efficient application means less product waste compared to conventional methods.

UVLACK is known for its versatility across multiple substrates like paper, cardboard, plastic films, and more. This adaptability makes it suitable for diverse industries ranging from packaging to promotional materials.

Comparison with Traditional Varnishes

In the printing and packaging industries, traditional varnishes have long been a mainstay.They serve to protect surfaces while enhancing visual appeal. However, they often fall short when it comes to durability and finish quality compared to UVLACK.

One major difference lies in the curing process. Traditional varnishes typically air-dry, which can lead to longer production times. In contrast, UVLACK uses ultraviolet light for rapid curing, allowing for quicker turnaround times on projects.

The finish is another point of comparison. While traditional options may provide some level of gloss or matte finishes, UVLACK offers superior sheen and clarity. This results in vibrant colors that truly pop on labels and printed materials.

When considering protection against environmental factors like moisture or scratches, UVLACK outperforms traditional varnishes significantly. Its robust formula creates a strong barrier that prolongs the life of labels and prints.

Additionally, UVLACK’s eco-friendly properties set it apart from many conventional alternatives laden with harmful solvents. As businesses increasingly prioritize sustainability, choosing UVLACK aligns well with modern environmental standards without compromising quality.

Safety and Environmental Compliance

When considering UVLACK, safety and environmental compliance are paramount.The formulation of this high-end UV coating complies with strict industry standards. It ensures that it can be safely used in various applications without compromising quality.

Low concentrations of volatile organic compounds (VOCs) are present in UVLACK. This makes it a favorable choice for businesses looking to reduce their environmental footprint. With lesser VOCs emitted during application, the impact on air quality is significantly minimized.

Moreover, this varnish is free from hazardous materials commonly found in traditional coatings. Users can apply UVLACK with confidence knowing they’re using a product designed with health and safety in mind. Proper handling guidelines further enhance its safety profile.

Adhering to regulations set forth by organizations such as OSHA and EPA ensures that businesses remain compliant while utilizing UVLACK in their operations. Regular testing confirms that the product maintains these high standards consistently.

Companies committed to sustainability will find that choosing UVLACK aligns with eco-friendly practices. Utilizing this advanced coating not only meets legal requirements but also reflects corporate responsibility toward protecting the environment.

Tips for Optimal Application

Achieving the best results with UVLACK requires careful attention to detail during the application process. Start by ensuring that your surface is clean and free from dust or grease. Any contamination can affect adhesion and result in an uneven finish.

Next, consider the ambient conditions where you are working. Ideal temperature and humidity levels play a crucial role in curing time and overall performance. Aim for a controlled environment to facilitate optimal drying and ensure that your varnish cures correctly.

When applying UVLACK, use equipment suited for its viscosity. Whether you’re using rollers, sprayers, or brushes, make sure they’re compatible with UV coatings. This choice will help maintain an even coat across your project.

Apply the varnish evenly to avoid pooling or drips which can mar the final appearance of your labels or prints. A thin layer often yields better results than several thick applications; this ensures quick curing under UV light.

Be mindful of curing time after application before handling any finished products. Properly cured surfaces not only enhance visual appeal but also improve durability against wear and tear over time.

Common Industry Uses

UVLACK finds extensive applications across various industries due to its versatility and high-performance characteristics. The creation of labels is among its most popular applications. Businesses utilize UVLACK to create vibrant, eye-catching labels that withstand wear and tear while maintaining their visual appeal.

Another significant application lies within the packaging sector. Brands often choose UV-coating for product packaging as it enhances durability against moisture, fingerprints, and scratches. This ensures that products maintain a professional look on retail shelves.

The printing industry also benefits hugely from UVLACK. Printers apply this coating to enhance color depth and improve overall finish quality on printed materials like brochures or business cards. The quick drying time further streamlines production processes.

In addition to these sectors, promotional items frequently feature UVLACKing. Items such as posters or flyers gain an extra layer of protection while achieving a glossy finish that attracts consumer attention.

The cosmetic industry employs UVLACK for its packaging solutions. It helps ensure that makeup products remain safe from external elements while providing an elegant presentation that appeals to customers looking for quality beauty products.

Conclusion and Recommendations

Choosing UVLACK for your printing and labeling needs offers a multitude of advantages. Its superior UV coating technology ensures that your labels are not only visually striking but also resistant to wear, moisture, and fading. The versatility of UVLACK allows it to be applied on various surfaces, making it suitable for diverse applications in packaging and branding.

For businesses looking to enhance their product presentation while maintaining durability, UVLACK is an excellent choice. It outperforms traditional varnishes by providing a glossy finish that attracts attention without compromising on safety or environmental standards.

When planning your next print job or label design, consider integrating UVLACK into the process. This premium coating can elevate the quality of your products significantly. Whether you’re involved in food and beverage packaging or cosmetics labels, the benefits of using this advanced varnish will surely reflect positively on consumer perception and brand reputation.

Investing in high-quality materials like UVLACK will ensure that your printed products stand out while meeting industry demands for durability and aesthetics. For best results, follow application tips provided by manufacturers to maximize performance across different media types. Embrace innovation with UVLACK—it’s more than just a finish; it’s a game changer for modern printing needs.